Stronger Than Steel, Tougher Than Kevlar – Spider Silk’s Secret Finally Revealed

Spiders don’t just spin webs—they engineer them. By stretching their silk as they spin, spiders strengthen the fibers at the molecular level, aligning proteins and forming extra bonds that boost durability.

Did you know? You can comment on this post! Just scroll down

Scientists have now cracked this secret using computational simulations and lab experiments, paving the way for bioengineered silk with game-changing applications, from medical sutures to ultra-strong body armor.

Spiders Strengthen Their Silk with Stretching

When spiders spin their webs, they use their hind legs to pull silk from their spinnerets. This pulling action does more than just release the silk—it strengthens the fibers, making the web more durable.

A new study from Northwestern University reveals why stretching plays such a crucial role. Using computer simulations, researchers found that as spider silk stretches, its protein chains align, and more molecular bonds form between them. These changes make the fibers significantly stronger and tougher.

Engineering Tougher, More Versatile Silk

To confirm these findings, the team conducted lab experiments using engineered spider silk. Their results could help scientists develop advanced silk-inspired materials for a variety of uses, from biodegradable surgical sutures to ultra-tough body armor.

“Researchers already knew this stretching, or drawing, is necessary for making really strong fibers,” said Northwestern’s Sinan Keten, the study’s senior author. “But no one necessarily knew why. With our computational method, we were able to probe what’s happening at the nanoscale to gain insights that cannot be seen experimentally. We could examine how drawing relates to the silk’s mechanical properties.”

Spiders: Natural Masters of Fiber Design

“Spiders perform the drawing process naturally,” said Northwestern’s Jacob Graham, the study’s first author. “When they spin silk out of their silk gland, spiders use their hind legs to grab the fiber and pull it out. That stretches the fiber as it’s being formed. It makes the fiber very strong and very elastic. We found that you can modify the fiber’s mechanical properties simply through modifying the amount of stretching.”

An expert in bioinspired materials, Keten is the Jerome B. Cohen Professor of Engineering, professor and associate chair of mechanical engineering and professor of civil and environmental engineering at Northwestern’s McCormick School of Engineering. Graham is a Ph.D. student in Keten’s research group.

Stronger Than Steel, Tougher Than Kevlar

Researchers have long been interested in spider silk because of its remarkable properties. It’s stronger than steel, tougher than Kevlar and stretchy like rubber. But farming spiders for their natural silk is expensive, energy-intensive and difficult. So, scientists instead want to recreate silk-like materials in the lab.

“Spider silk is the strongest organic fiber,” Graham said. “It also has the advantage of being biodegradable. So, it’s an ideal material for medical applications. It could be used for surgical sutures and adhesive gels for wound-closure because it would naturally, harmlessly degrade in the body.”

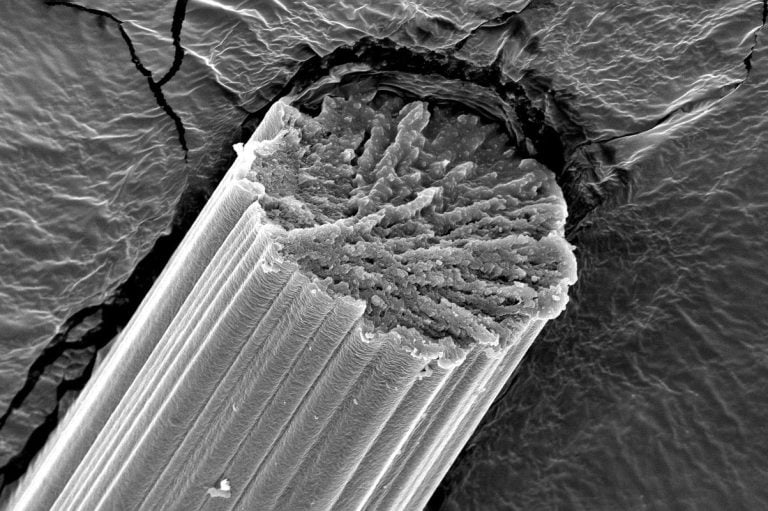

Study coauthor Fuzhong Zhang, the Francis F. Ahmann Professor at Washington University (WashU) in St. Louis, has been engineering microbes to produce spider-silk materials for several years. By extruding engineered spider silk proteins and then stretching them by hand, the team has developed artificial fibers similar to threads from the golden silk orb weaver, a large spider with a spectacularly strong web.

Simulating Stretchiness: The Science Behind Strength

Despite developing this “recipe” for spider silk, researchers still don’t fully understand how the spinning process changes fiber structure and strength. To tackle this open-ended question, Keten and Graham developed a computational model to simulate the molecular dynamics within Zhang’s artificial silk.

Through these simulations, the Northwestern team explored how stretching affects the proteins’ arrangement within the fibers. Specifically, they looked at how stretching changes the order of proteins, the connection of proteins to one another and the movement of molecules within the fibers.

Molecular Magic: How Stretching Aligns Proteins

Keten and Graham found that stretching caused the proteins to “line up,” which increased the fiber’s overall strength. They also found that stretching increased the number of hydrogen bonds, which act like bridges between the protein chains to make up the fiber. The increase in hydrogen bonds contributes to the fiber’s overall strength, toughness, and elasticity, the researchers found.

“Once a fiber is extruded, its mechanical properties are actually quite weak,” Graham said. “But when it’s stretch up to six times its initial length, it becomes very strong.”

From Theory to Reality: Testing the Fibers

To validate their computational findings, the team used spectroscopy techniques to examine how the protein chains stretched and aligned in real fibers from the WashU team. They also used tensile testing to see how much stretching the fibers could tolerate before breaking. The experimental results agreed with the simulation’s predictions.

“If you don’t stretch the material, you have these spherical globs of proteins,” Graham said. “But stretching turns these globs into more of an interconnected network. The protein chains stack on top of one another, and the network becomes more and more interconnected. Bundled proteins have more potential to unravel and extend further before the fiber breaks, but initially extended proteins make for less extensible fibers that require more force to break.”

A New Perspective on Spiders

Although Graham used to think spiders were just creepy-crawlies, he now sees their potential to help solve real problems. He notes that engineered spider silk provides a stronger, biodegradable alternative to other synthetic materials, which are mostly petroleum-derived plastics.

“I definitely look at spiders in a new light,” Graham said. “I used to think they were nuisances. Now, I see them as a source of fascination.”

Reference: “Charting the envelope of mechanical properties of synthetic silk fibers through predictive modeling of the drawing process” by Jacob J. Graham, Shri V. Subramani, Xinyan Yang, Timothy M. Russell, Fuzhong Zhang and Sinan Keten, 7 March 2025, Science Advances.

The study was published in the journal Science Advances and supported by the National Science Foundation.

Article Posted 2 Months ago. You can post your own articles and it will be published for free.

No Registration is required! But we review before publishing! Click here to get started